Print3r: Taming My 3D Printing Chaos with a Desktop App

Introduction

I’ve recently dived headfirst into the world of 3D printing, and while it’s been an incredibly rewarding hobby, I quickly found myself drowning in a sea of details. Keeping track of what I’ve printed, how much filament each model consumed (especially across multiple plates), and the actual cost of it all became a chaotic mess of forgotten notes. I needed a better way to manage my prints, my filaments and cost.

So, I built Print3r, a custom desktop application to bring order to my 3D printing chaos. 😵💫

The Why: A Need for Organized Printing

As my collection of prints and filaments grew, so did the mess.

- How much did that multi-plate model actually cost to print?

- How much of my favorite PLA+ filament do I have left?

- What’s the total cost of all the parts for my latest project?

I needed a centralized place to store print histories, manage my filament inventory, and calculate the true cost of each print, right down to the electricity used.

The Solution: Print3r

![]()

Print3r is a dedicated tool designed to solve these problems. It’s built with Electron, making it a neat, self-contained desktop app. Here’s what it does:

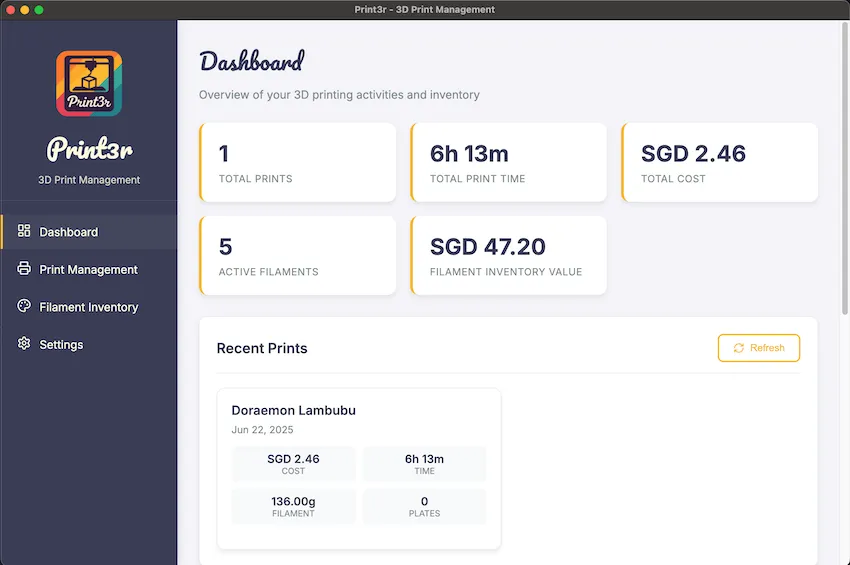

Dashboard Overview

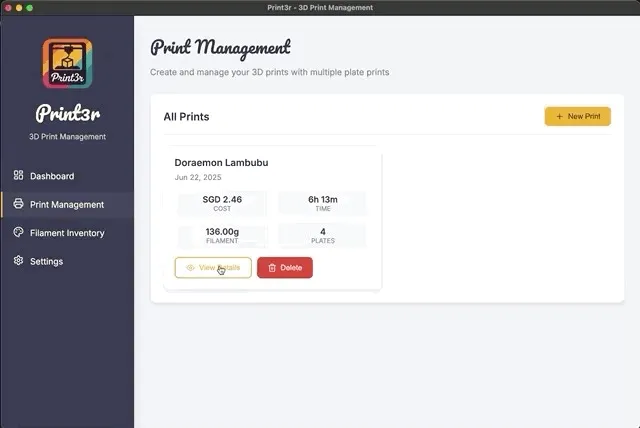

Print History

Every print is logged with its history, giving me a complete overview of my projects. I’m also able to record multiple build plate prints in a single print model record.

Granular Filament & Cost Tracking

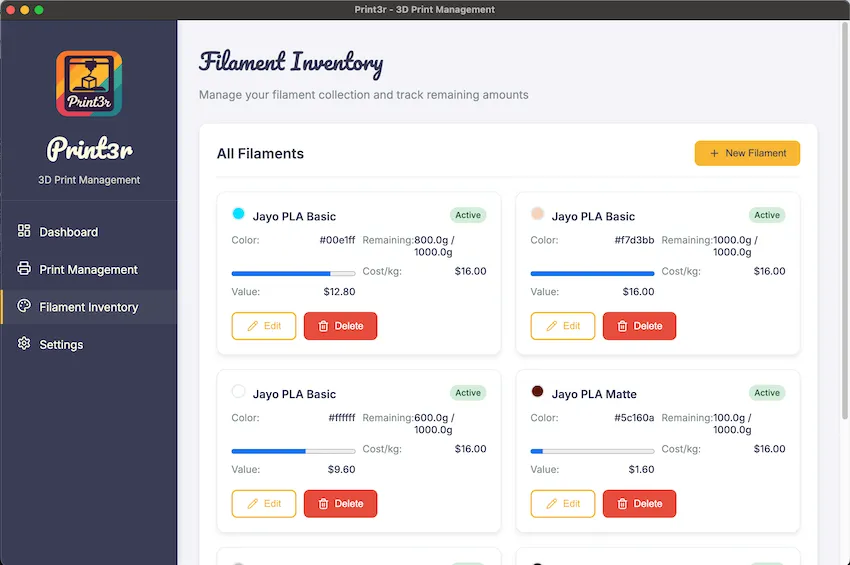

This is the core of Print3r. I can catalog my entire filament inventory, including:

- Brand: Bambulab or 3rd Party brands

- Material: PLA Basic, PLA+, PLA Matte, High Speed PLA

- Price: I input the cost of each spool, which is then used for cost calculations

The app meticulously tracks filament usage for each print, even when a model is split across multiple plates. It then combines the filament cost with the electricity cost (based on configurable rates and print time) to give me a precise total price for every single model.

A 6-Hour Sprint with Cursor

One of the most exciting parts of this project was how quickly it came together. Using Cursor, I went from idea to a fully functional Electron application in just 6 hours. The AI-assisted workflow allowed me to focus on the logic and features without getting bogged down in boilerplate code.

Conclusion

Building Print3r will become a great companion to my 3D printing hobby. It brings a level of organization and insight that I was missing, allowing me to focus more on the fun part of printing.

This project was a fun, fast-paced “build-to-learn” project that helped to solve a real-life headache of mine.

The source code is available on GitHub.

This post is part of my Build to Learn series, where I explore new technologies and development approaches through hands-on projects.

← Back to blog